FLIR cameras keep Dovecote Park meat production hall safe from fire incidents

The production hall of meat producer Dovecote Park in Stapleton, Yorkshire (UK) is buzzing with activity 24/7. There, the company combines traditional British butchery craft with advanced food processing technology to produce some of the most exceptional meat products. The company is committed to keeping its workforce safe and its productivity intact. It’s for those reasons that Dovecote Park invested in early fire detection technology from FLIR.

Dovecote Park was established in Yorkshire, UK in 1997. The company supplies British beef, veal and venison for the retail, fine dining and food service sectors nationwide. Among Dovecote Park’s customers are upmarket supermarket Waitrose, Gourmet Burger Kitchen, Burger King and Wentbridge House. The company controls the entire meat production process: from procuring livestock from its carefully picked group of farms, through butchery, retail packaging to dispatch.

Hot equipment indicates fire hazard

Keeping the production process going in the main hall in Yorkshire is critical. Unfortunately, with machinery that is operated 24/7, fire incidents are not uncommon in the food production sector. The fire incident in a meat production hall in Wolverhampton in January 2024 is just one example of how things can escalate quickly. The consequences of a fire outbreak are potentially devastating. Not only is there a risk of human casualties and damage to the infrastructure, but affected companies also need to take into account long periods of business interruption and damage to the brand reputation.

Management at Dovecote Park takes fire safety to heart. They identified a fire risk in the roof voids of the main production hall. All critical devices, for example motors, pumps, electrical cabinets and distribution boards, which power the food production machinery (for cutting and packing) on the production floor. The reason for keeping this equipment in the roof void, is that it must be separated from the food-grade factory floor, but still close enough to efficiently power the machinery below.

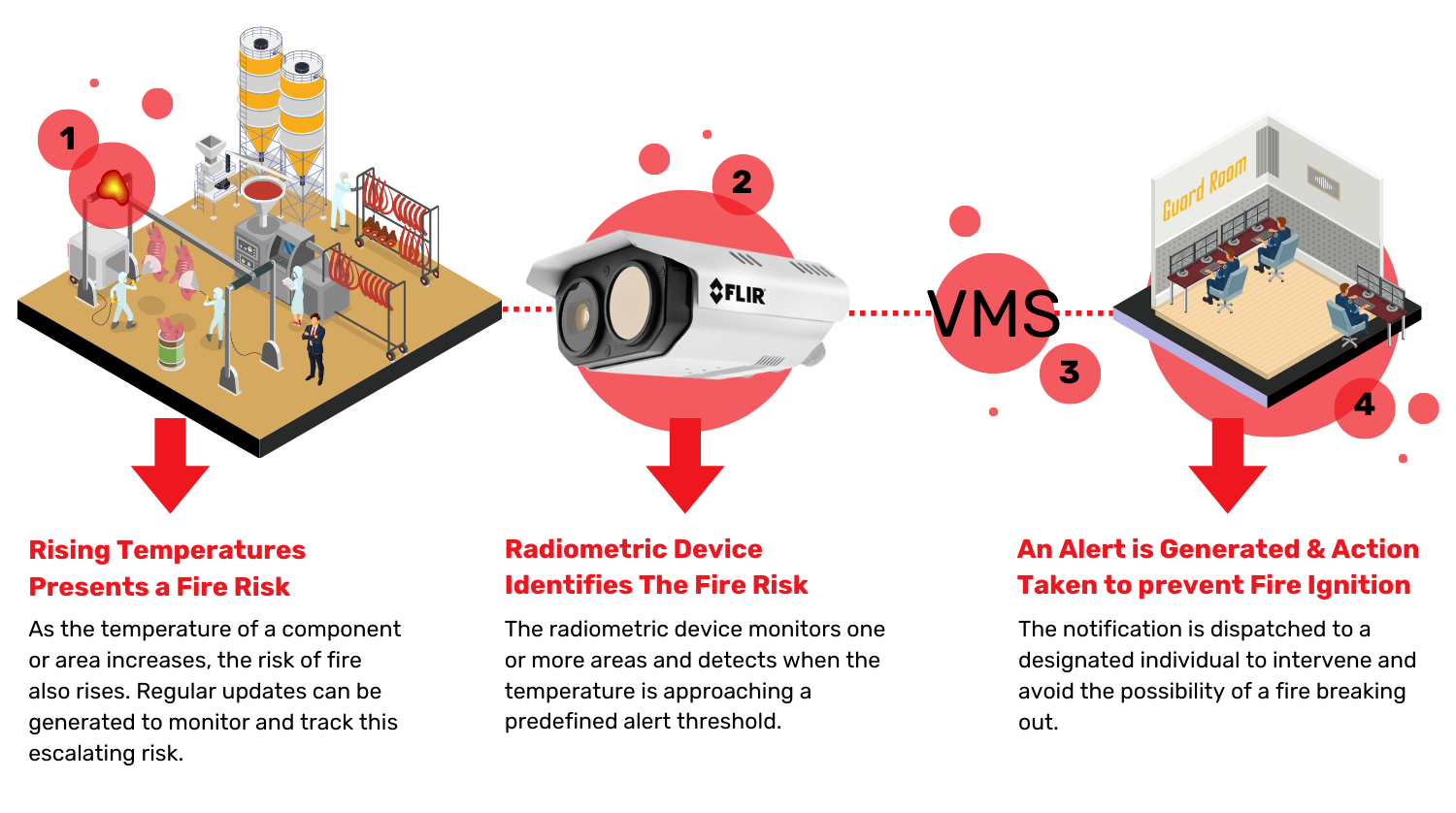

When this equipment is deteriorating, gets worn, or reaches end of life, it typically gets hot. Mechanical problems like worn pumps or damaged bearings, or electrical problems like failing circuit breakers, all have one thing in common: they start to heat up. When unnoticed, this heat buildup can be the start of a devastating fire.

Thermal imaging beats fire suppressants

In their search for a technical fire prevention solution, the team at Dovecote Park first considered a Sprinkler fire suppressant system. However, this idea was quickly abandoned, since it proved not to be the right solution for the production hall environment.

“Not only is it expensive to cover a large area with a Sprinkler system, but such a system will only be activated when a fire has already developed. This is much too late, because by that time, the damage is done,” says Nick Dunn HS&E Manager at Dovecote Park. “In addition, in a production area full of electrical and mechanical equipment, a Sprinkler system can cause significant water damage.”

Working in partnership with system integrator WRS Solutions, Chris Eccles, Sales Director of FLIR Partner Business Insight 3 (Bi3) proposed a solution to install multiple FLIR FH-Series R cameras in the roof voids. The FLIR FH-R is a ruggedized, multispectral fixed sensor that combines a thermal, radiometric stream with a 4K visible camera to provide rapid, early fire detection and visual verification of the incident as it unfolds. Thermal imaging is a trusted, non-contact method of measuring temperatures, which can help to prevent fires by detecting hot spots before they reach their ignition temperature.

When a hot spot or predefined temperature threshold is exceeded, an audio/visual alert is sent to the company’s security operators through a connected Video Management System (VMS) or relay output. Upon seeing the incoming alert, the team can then decide which response tactics are needed. The FH-R sensors also have integrated smart analytics, allowing them to track people movements. The sensors allow operators to easily adapt the threshold temperatures to the specific equipment that needs to be monitored. So, it’s perfectly possible to monitor different temperature ranges in one roof void.

Long established FLIR partner (Gold Level) Bi3 added value by proposing not just a product, but an entire solution. In the past, they have provided early fire detection solutions using the FH-R Series at several other sites, so when they were approached by WRS Solutions to provide a similar solution at Dovecote Park, they already had all the technical experience to meet the challenge. Installations in roof voids are some of the most difficult, and for their part, WRS Solutions provided a flawless integrated solution with minimum disruption to operations at Dovecote Park.

24/7 fire security awareness

In addition to the security team, the alerts are also sent to the engineering department and to Nick Dunn in his capacity as Health, Safety and Environmental manager. “The more visibility we can get over our production hall, the better,” Nick says. “The FLIR thermal cameras have certainly made our lives a lot easier. They give us peace of mind, because we can now be proactive in the maintenance of our equipment, instead of reactive. From the moment something gets hot, our maintenance team can attend to it.”

Thermal imaging just works. It’s very effective in preventing fires and avoiding business disruption. That was the conclusion one year after the installation. In the year that had passed, two incidents had already been detected. One potentially catastrophic incident was a motor bearing that had started to overheat. If it hadn’t been picked up in time by a FLIR camera, this would have resulted in failure and in serious business disruption. A second, less serious incident was a steam pipe that broke down. A FLIR camera picked this up as well and the maintenance team could prevent any further damage.

Example visual from a FLIR FH-Series R deployed at Dovecote Park

Peace of mind and financial benefits

Today, the several roof voids above the production hall have over 30 FLIR FH-R cameras. WRS Solutions completed the installation in a matter of weeks. Kevin Polkey, Regional Director at WRS, acknowledges that FLIR cameras were the ideal early fire detection solution for Dovecote Park.

“The investment in thermal imaging cameras is much less compared to fire suppressant systems,” says Kevin. “Apart from preventing physical damage and business loss, thermal cameras help to protect a brand’s reputation as well, especially in a highly competitive market like food production.”

Robert Groom, sales manager at FLIR says: “This is a fine example of where proven FLIR technology in the hands of skilled and experienced industry professionals, such as Bi3 and WRS, can not only protect people and property, but also deliver a real return on investment.”

“The effectiveness of FLIR’s radiometric technology in the food processing industry cannot be understated. Unlike traditional fire suppression systems that react to fires, thermal imaging technology enables the prevention of fires before they start.

Successfully delivering this innovative solution necessitates a capable team, and with WRS and FLIR as partners on this project, a seamless installation and integration were achieved. This, resulting in immediate and tangible benefits for Dovecote Park.” – Chris Eccles, Sales Director At Business Insight 3

And last but not least, thanks to the installation of the thermal imaging cameras, Dovecote Park was able to significantly bring down its insurance premium for the production hall. “It’s safe to say that the investment in thermal imaging cameras has already paid itself back,” says Nick Dunn.

Burnt out circuit breakers detected before fire outbreak.