FLIR Total Solution for EV Battery Industry

EV Battery Production Quality, Safety, and Reliability

The electric vehicle (EV) industry is growing rapidly around the world, driven by a variety of factors, including government regulations, consumer demand for environmentally friendly transportation, and technological advancements that have made EVs more practical and affordable.

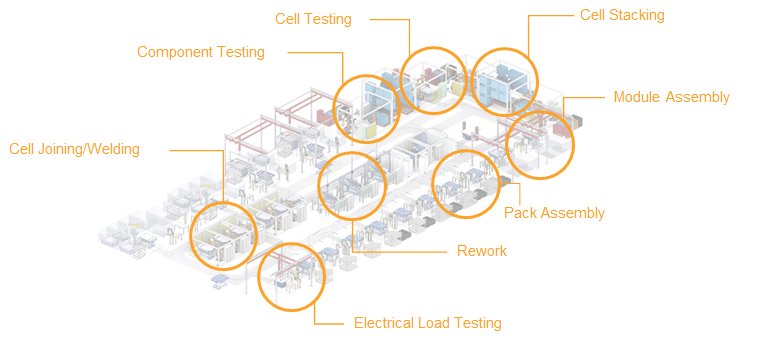

The whole industry chain consists of semi- and semi/fully-automated production lines that require smarter tools to keep pace. Long-term quality, product reliability, and worker and facility safety are also top priorities.

FLIR offers the total solution for improving EV battery quality, reliability, and safety through its line of thermal imaging cameras, automation sensors, and Test & Measurement products.

Battery Pack Quality and Safety Assurance

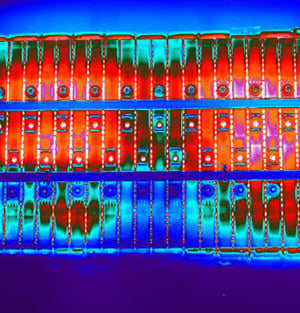

Identify potentially poor connections and underperforming cells and modules

Interconnections between cells, packs, and modules are welded and mechanically assembled connections; poor or loose connections will heat disproportionally.

Thermal cameras provide real-time, non-invasive thermal imaging data at every step, helping manufacturers identify defects, optimize thermal management, and ensure EV batteries meet quality and safety standards at every production stage.

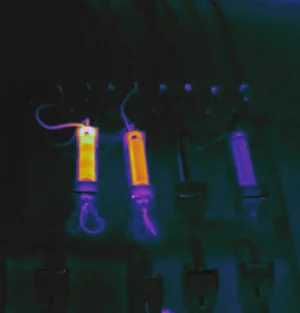

BMS Testing Support

Predictive maintenance fault components

Thermal cameras provide critical temperature data that empowers the battery management system (BMS) to make real-time decisions to maintain safe and efficient battery operation. This proactive approach to thermal management and fault detection helps maximize the performance, longevity, and safety of EV batteries.

Thermal Runaway Monitoring

Detect potentially dangerous conditions

Manufacturers partially or fully charge battery cells and modules during assembly, allowing the current to flow as they are connected. This results in increasing temperatures and current flow.

Unchecked thermal runaways can result in cataclysmic events. Thermal imaging can identify the thermal runaway conditions; when a thermal camera identifies an abnormally hot cell, the BMS can quickly isolate or cool the affected cell to prevent further escalation.

Continuous Automated Thermal Condition Monitoring

FLIR automated thermal cameras are a flexible, configurable solution to meet the needs of EV battery manufacturing. Fixed-mount models can identify a higher number of potentially loose connections and result in less end-of-line failures of the battery system. Integrating FLIR automated thermal cameras into production lines empowers manufacturers in several ways:

- Both visual and thermal monitoring

- Up to 640 × 480 (307,200 pixels) resolution thermal images

- Alarms anytime custom set temperature thresholds are crossed, so you never need to worry about missing a single defect.

- Easy to install and compatible with standard industrial protocols and video management systems including HMI, SCADA, and optional ONVIF S compatibility

FLIR Products for the EV Battery Industry

Infrared Thermography Training Resources

Infrared Thermography Training Resources

Sign up for scheduled infrared thermography training courses offered through the Infrared Training Center (ITC).

Learn more

Do you have a large group that requires thermography training? The ITC will organize an onsite training course.

Request training

Intelligence in Action with FLIR's Software Connectivity

Get in touch with us to discover the best software for your cameras

Related Articles

The Battery Innovation Center Uses High-Speed Thermal Imaging for Abusive Battery Testing

Read the story

Monitoring For Thermal Runaway To Prevent Fire In Electric Vehicle Battery Modules

Read the Story

Identifying Poor Interconnection On Electric Vehicle Battery Modules

Read the Story

Why Yacht Owners Are Adding Thermal Imaging Cameras to Minimise the Risk of Lithium-Ion Battery Fires

Read the Story